Product class

LOCATION:Home > Product class > Screw & barrel> alloy screw barrel

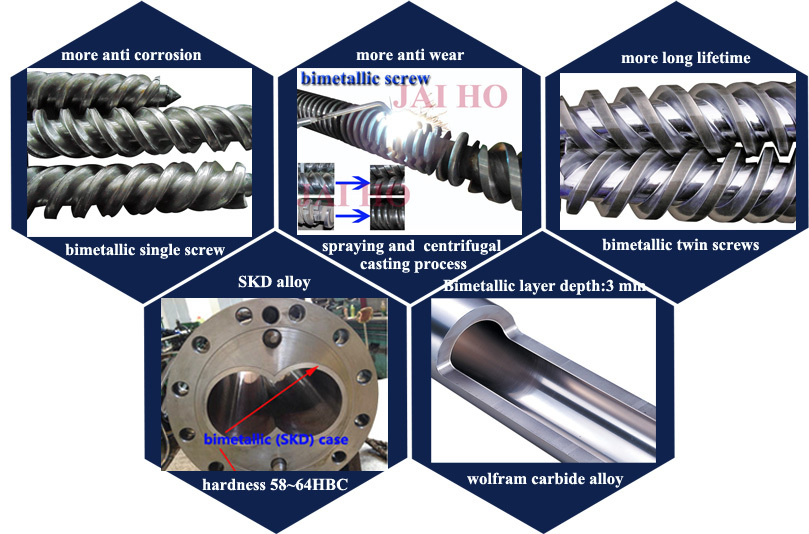

| Technical Information for bimetallic screw cylinder | |||

| Main Base materials | 1.38CrMoAlA (SACM645) | Main Alloy Materials | 1. Ni-based alloy/Deloro alloy |

| 2. SKD-61 (Special Tool Steel) | 2. Tungsten carbide/Wolfram carbide | ||

| 3. 42CrMo (Ultrahigh StrengthSteel) | 3. NiCo-based alloy | ||

| 4. DC53 (Cold WorkDie Steel) | 4. Fe-based alloy | ||

| 5. W6Mo5Cr4V2 (High-SpeedToolSteel) | 5. Co-based alloy | ||

| Processing Technics | 1. Heat treatment | Technical parameters | Nitriding layer depth:0.5-0.8mm |

| 2. Quenching | Nitrided hardness:900-1000HV | ||

| 3. Nitriding treatment | Bimetallic layer depth:3 mm | ||

| 4. Bimetallic alloy welding for screw | Bimetallic hardness:57~69HRC | ||

| 5. Bimetallic alloy centrifugal casting for barrel | Hard-chrome plating hardness after nitriding:≥950HV | ||

| 6. Hard-chrome electroplating | Chrome-plating layer depth:0.03-0.09mm | ||

| Linearity of screw:0.015mm | Surface roughness:Ra 0.4 | ||

| Bimetallic screw and barrel for Extruder machine |

| Material |

| Alloy-Steel of High-quality |

| 1) 38CrMoALA (JIS SACM645) |

| 2) 42CrMo (JIS SCM440) |

| 3) CW6Mo5Cr4V2 |

| 4) 9Cr18Mov replicas bolsos hermes |

| 5) SKD11 |

| 6) SKD61 |

| Heat-treatment : |

| Nitriding or Bimetailic |

| Size:Φ20mm~Φ300mm |

| Ratio of length to diameter L/D= 15~55 |

| Packing:AA grade worden Case |

Ningbo JAIHO Machinery Co.,Ltd.(JAIHO Group) | Address:Room 3-11,Green Apple Business Plaza,NO.672,Yongfeng West Road,Haishu District,Ningbo City | Tel: 0574-87359334

Fax: 0574-89086758 | E-Mail: thomas@jaihogroup.com.cn Website: www.jaihogroup.com.cn replica uhren | orologi replica